The Chubb Archive is part of The History of Locks Museum Resources

Contact our curator for more information

© 2004 - 2016

Your one-stop resource for dating & information on vintage and antique Chubb Locks, Safes & Security Equipment

Export Is Fun

Mr. D.R.E. Ibbs’ personal memories of his 41 years with Chubb

3. Back to Work.

I resumed working for Chubb on January 1st 1958. It had been decided that in order to allow me to settle back into civilian life and before the upheaval of a move to London, I should act as personal assistant to Mr Reg Hoye, the Lock Works Manager. A number of very large government contracts were in hand and it had been decided that in order to meet contract delivery dates, some of the work should be carried out at the Lock Works in Leyton, Essex, which Chubb had acquired two years earlier during the takeover of Hobbs Hart & Co.Ltd.

My job was to ensure that all the materials necessary for the locks were dispatched to London in good time. Mr Hoye confided in me that he had grave reservations regarding off-loading the work to Leyton, as at that time, all lock parts were only roughly machined and then hand finished by locksmiths. The manager at Leyton, Mr Markham, had indicated that he would use a revolutionary new method of producing locks, whereby the initial machining would be extremely accurate and the locks could be assembled by female labour with a minimum of hand finishing. Reg Hoye felt that with the machines and tools available, such production methods were not viable and he had grave doubts whether the experiment would be successful.

Mr Hoye therefore asked me to keep a very careful eye on the situation and advise him immediately final assembly started. This eventually lead to some friction with Alfred Markham, who made an accusation at board level, that I was coming to the Leyton factory to spy on the situation and there had been occasions when he did not know I was on the premises. Reg Hoye took me to task over this but I assured him that each time I visited, before setting foot on the shop floor I went to Mr. Markham’s office to report my arrival. If he was too busy to see me I asked his secretary to let him know I was on site. Reg said he felt the situation had obviously been blown out of all proportion; subsequently, during a visit to Wolverhampton, Mr Markham took me on one side and apologised for his comments.

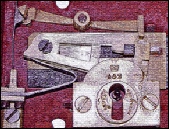

Finally, all the machined parts were ready for assembly and I reported this to Reg Hoye. He instructed that on my next visit to Leyton, I should be accompanied by a lock works Chief Inspector. On arrival at Leyton we reported to Mr Markham and were shown to the assembly line where the first finished locks were ready for inspection. The Inspector selected a lock at random, tested it and passed it to me to. It worked wonderfully well and I felt that all our worries had been unnecessary. He selected another and as he turned the key I could hear the mechanism grating. Again, he passed it to me and as my ears had told me, it worked like a bag of nails. Without further ado, the Inspector jumped up on the nearest bench shouting " Stop the job!". Assembly halted and having demanded the caps of all the small padlocks which had been produced should be removed, he proceeded to carry out a 100% inspection on the finished locks.

The visual results were appalling! The first lock selected had worked so well because the lever gates had been opened out with a file. The next lock, which had operated noisily, had been assembled from unaltered parts but worked so badly as to be quite unacceptable. We returned to Wolverhampton in a very depressed state and the next morning I was called in to Reg Hoye's office, where the Chief Inspector had already made a report. Reg looked extremely grim and asked my version of what had happened. Quite what happened later at a high level I do not know but all the machine parts were returned to Wolverhampton and the locksmiths worked many hours of overtime to assemble the padlocks. The strain on Reg Hoye must have been intolerable but he continued to treat me very kindly.

Knowing the time for me to depart to London was fast approaching he asked what I would like to do in the closing few weeks. I requested permission to have some training with the locksmiths - something not usually given to student apprentices. He kindly agreed and in the ensuing weeks, I spent an interesting time assembling a set of locks which were subsequently used on my new house in London. I also learnt a great deal about combination locks which was particularly valuable to me in my subsequent career.

During this time I made frequent visits to London in order to find somewhere to live. It soon became obvious that renting property was out of the question but the with the help of London staff, we eventually found an estate of small semi-detached houses which were being built at Cheshunt. One of these was available, with a completion date to suit my requirements. The problem was that in the six months I’d been out of the forces, I had not been able to save very much money and my total financial resources were 40 pounds. The estate agent advised that I simply did not have enough to be granted a mortgage, even if I could make a deposit of 450 pounds from the total purchase price of 2450 pounds. This was totally out of the question and with great embarrassment, I had to contact Mr Dunham and explain the situation to him. He reacted swiftly by contacting the estate agent, who was also dealing with the mortgage application, and arranging for the Company to make me a loan of 450 pounds on extremely favourable terms. The deal was done and I became the owner of my first property. Furnishings were going to be a problem but with the help of our respective families, we were able to cope.

The rest of my time of Wolverhampton passed in a swirl of personal activity and in the factory, great changes were taking place. Reg Hoye resigned in order to go into holy orders and Alfred Markham was appointed Lock Works Manager. He brought with him his vision of producing commercial locks in a much faster and cheaper way. Although there were one or two disappointments along the way, mainly in the form of the so-called ‘Blue Flash’ range, the technology was developing and finally, many of the commercial locks were produced by very accurate machining and assembled by female labour.

Finally, in August 1958, I handed back the keys of my rented property in Wolverhampton and packing my few possessions, moved to my new home at Cheshunt in Hertfordshire.

Home | Previous Page | ToP | Next Page

| Chubb 1818-1990s |

| Chatwood-Milner |

| Chubb Family |

| Early Sales/Offices/ChubbGroup/1980s & on |

| The Detector Mechanism |

| Photographs |

| Chubb Money Boxes |

| The Aubin Trophy |

| Lock Number 696 |

| Williams acqusition |

| Arthur Briant |

| Ibbs - Export is Fun |

| Peter Gunn |

| Back to Work |

| First Steps |

| My Export Career begins |

| The Happy Years |

| Export Manager |

| Back to The Midlands |

| Back to The Midlands - part 2 |

| Australia |

| The Midlands - again! |

| The Final Years |

| Conclusions |

| Slingsby Dart T51 Sailplane |

| Latest News |